工作原理

Operating principle

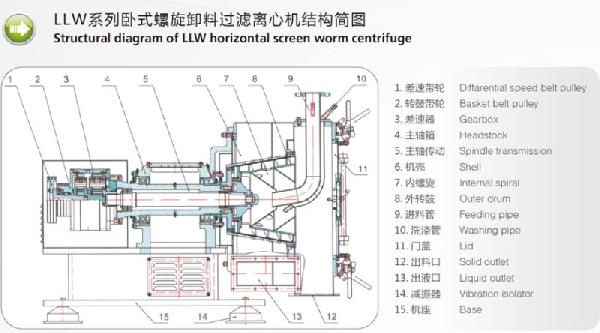

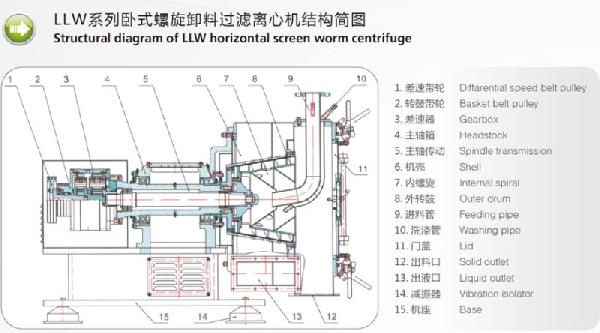

LLW型卧式螺旋卸料过滤式离心机是种能耗低性能稳定、分离效果好的机型。分离过程中的进料、脱水、洗涤、卸料等工序连续完成,生产效率和自动化程度高,是种先进的固液分离设备。悬浮液从进料管进入螺旋内腔,并通过螺旋小头接近锥端底部的喷料口进入转鼓,在离心力场的作用下,料浆中的液相通过铺设在转壁上的筛网被过滤出去,固相颗粒则被截留在转鼓内;同时,转鼓内的固相颗粒在离心力和螺旋与转鼓之间的相对差速作用下,从转鼓小端向转鼓大端运动,在此运动过程中,由于回转直径的加大,离心力得到快速递增,固相从初始进入时的较高含湿量到排出转鼓时达到*低含湿量固相,从而实现固液相自动、连续的分离。离心机内置洗涤管,可在滤饼过滤的同时对滤饼进行洗涤。由于是薄层滤饼洗涤,洗涤效果好,洗涤液消耗低。在转鼓背面可设计蒸汽管,对转鼓背面结晶的物料进行高温洗涤。螺旋差速器有摆线差速器,行星差速器和液压差速器三种配置,满足不同物料的分离。

LLW series conveyor discharge screen centrifuge is the one with low eneray consumptionstable performance and good separating effectiveness. The separation processing from feeding to dewatering,cleaning and discharging is continuous with high processing efficiency and high degree of automation. Jt is the advanced separation equipment The feed suspension is introduced to the centrifuge through a feed pipe and into the feed distribution chamber and is jetted into the baske through the hole near the cone point of the convelior.Under centrttugal force the solids filtrate trm the liquid and settle against the basket wall. while the clarified iquid exits over the overflow screen. The solids in the conical basket are conveved up from the smaller end to the bigger end while the convevor turns at a sliahtly diferent speed. The biager diameter is.the biaaer centrifuaal force produces to separate the liquid/solids.The solids are dried when thev are drained out the basket.The washing pipe incorporated in the centrifuge can not only filter the solid cake,but also wash the cake. The thin cake washing achieves qood effects of washing and consumes low amount of washling Jiquid.A steam pipe may be provided on the back of the basket so as to wash the crystattized m als on the back at high temperature Gearbox: cycloidal gearbox,planetary gearbox and hydraulic gearbox so as to suit for separation of different materials.

LLW卧式螺旋卸料过滤式离心机广泛应用于化工、食品、盐、

采矿、制药等行业。因其分离原理和结构特性,其对物料的针对性也较强

主要话用干具有较大颗粒度,对颗粒破碎没有严格要求的物料。在选型时应进行物料分析和相应的试验,以确定其话用和分离性能。(我

们有超过上百种物料应用数据及成功经验,在选型时可与我们的技术人员进行沟通,以便获取更详尽的资料)

1165

1165