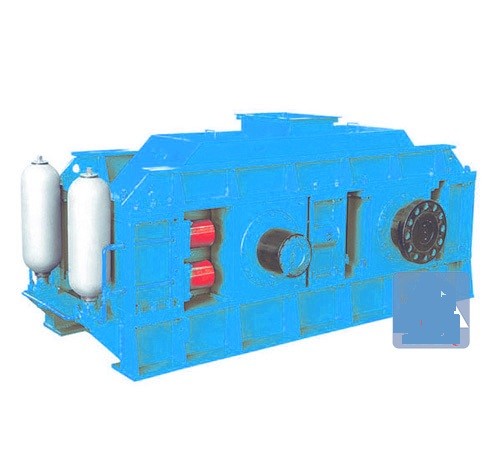

对辊式

破碎机是破碎设备的一种, 因结构简单, 方便维护, 性能稳定,能耗低, 经久耐用而广泛使用在水泥, 化工, 电力, 矿山, 冶金, 建材, 耐火材料, 煤矿等各个领域。Double-roll crusher is one kind of crushing equipment, It has feature of simple structure, convenient maintenance, stable performance, low power consumption, durable and widely used in many areas such as cement, chemical,electric power, mining, metallurgical, building materials, refractory,coal, etc.

1.对辊破碎机设计合理, 机构简单, 占空间小, 操作方便Double-roll crusher reasonable design, simple structure, small space occupation, convenient operation.2.本机采用了**的机械结构设计和合理的动力匹配, 从而很大降低了电能的损耗,比其它规格破碎机节能30%左右。Adopts the optimal mechanical structure design and reasonable power matching, thereby greatly reducing the power loss, about 30% energy saving than other crushers.3.内部装有防尘板,密封性能好,避免了破碎后的细小物料的扬溅,粉尘少,工作噪声低,工作环境有较大的改善。Equipped with dust-proof plate, good sealing performance, avoiding the broken tiny splash of materials, little dust, low noise, use a good environment4. 磨料辊体重新进行优化设计,设备使用终身不需要换磨机辊体,而旧型对辊机使用一年就需拆开大修,更换辊体。Abrasive roller re optimize design, does not need to change the roller lifelong, while the old roller crusher use for one year would need to open repair, replace the roller.5. 本机磨辊上装有可更换耐磨衬板,耐磨衬板采用国内先进耐磨材料,具有使用寿命长,不易损坏,方便维修等优点。连续使用寿命可达一年以上,磨损严重时,移开机盖即可更换。维修量小,成本低。Equipped with a replaceable abrasion resistant lining plate, the wear-resistant liner using the domestic advanced wear-resistant materials, has the advantages of long service life, not easy to damage, convenient repair etc.. The continuous service life of up to one year or more, wear serious, remove the cover can be replaced. A small amount of maintenance, low cost.

6. 本机装有安全防护装置,当有意外金属铁件进入破碎腔后,防护装置动作,铁件漏出设备正常运转。Equipped with safety protection device, when have unexpected metal iron into the crushing chamber, the protection device action, iron leakage equipment normal operation

7. 本机磨料辊体辊缝在1mm~20mm间任意可调,根据破碎粒度的要求调好辊缝后,破碎粒度能得到可靠控制,全部以理想粒度由破碎腔下方排出。the abrasive roller roll gap arbitrary adjustable in between 1mm ~ 20mm,according to the requirements of the particle size adjust the roll gap, crushing size can be get reliable controlled, all final products in an ideal size discharged from the bottom of crusher chamber.

8. 结构简单合理,运行成本低,运转平稳,高效节能,破碎效率高,破碎比大。Simple and reasonable structure, low running cost, stable running, high- efficiency and energy saving, high crushing efficiency,big crushing ratio.9. 本机是低转速高压力对辊挤压的工作原理。物料由破碎机上部垂直落入破碎腔里,由两辊之间产生的强大压力挤压破碎下,物料大部分已经成为细小颗粒,剩余小部分颗粒状物料的内部已经产生大量裂纹。在进一步粉粹过程中,可较大地降低粉磨能耗, 提高产量。the roller crusher is low speed high pressure roll extrusion working principle. Materials vertical falling into the crushing chamber from the upper crusher, was extruded and broken by strong pressure generated by the two roll, most of materials has become small particles, the remaining small particle materials inside has generated a large numbers of cracks. In the course of further crushing process, can greatly reduce the grinding energy consumption and improve production.PDG-II型

(高铬合金辊圈,弹簧结构)high chromium alloy roller ring, spring structure

1151

1151