我公司为了解决人工制砂生产线、大型矿区的

尾矿污浆处理过程中的细砂部分流失,及人工制砂泥浆水无法处理造成污染等问题,特研制出SG系列细砂提取设备。

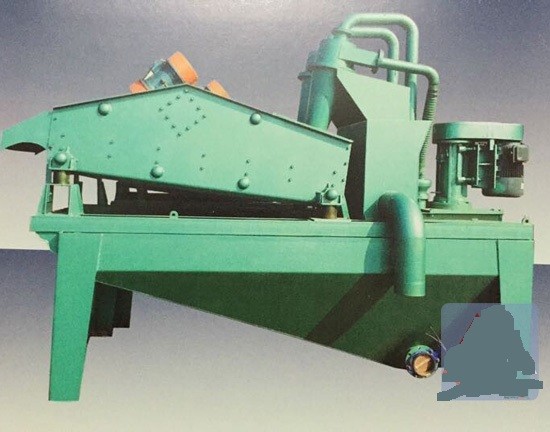

SG series sand recycling system is specailized in solutions, such as to solve the polution from artificial production line, large mining area of the tailings pulp processing part of fine sand erosion, and artificial sand slurry water cannot deal with.该设备由电机、耐磨泵、砂浆浓缩器、直线

脱水筛、清洗槽、返料箱等部件构成。工作过程:泥浆水流入清洗槽,通过耐磨泵将泥浆水送入浓缩器,经过浓缩器把污水和砂分离,砂经喷头到脱水筛,脱水后送入输送带。污水回到返料箱,分流入清洗槽,多余部分外泄。

Equipment principle:

The equipment consists of motor, wear pumps, mortar Inspissator, linear dewatering screen cleaning tank, container parts and other components form.

Working process: When muddy water flow into the cleaning tank, fed by wearable pump into the Inspissator, separate sewage and sand through the Inspissator. Through sprayer to dewateringscreen ,the sand will be sent into conveyor belt after dehydrating. At last, sewage return to the container and splitinto the cleaning tank, the excess part leak.

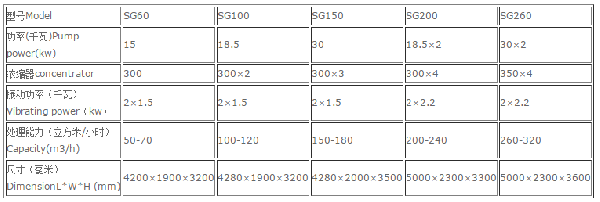

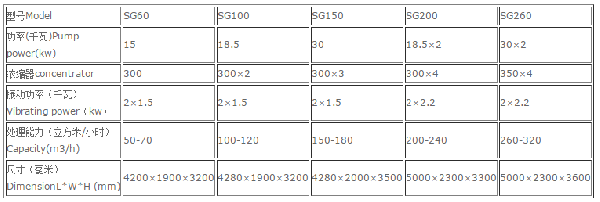

Parameter:

注:水泵分立泵与卧泵,处理效果200目以上含固率70%-80%注:处理能力根据含固率不同,其结果有所不同。

Note:The pump has vertical pump and horizontal pump.The processing effect is more than 200 mesh and solid rate 70%-80%.

Note: Capacity is different according to solid rate.

产品特点:该细砂回收设备,可以有效降低细砂的流失量,使其控制在5~10%之内。很好地解决了人工物料加工系统出现的成品砂细度模数偏高、石粉含量偏低的难题。·

脱水筛、筛板与喷头系本公司联合几家高分子研究单位通过反复试验,研制出的合成塑料,使其磨损寿命比钢板大5~6倍,且不易堵孔。·

细砂回收设备可回收排放总量中90%的细颗粒物料,具有其他设备无可比拟的技术和经济优势。

细粒得到充分回收,减少了沉淀池的工作量,降低了沉淀池的清理成本。

细砂回收系统减少了细料自然堆放时间,可直接转运,供应市场。

可根据用户的不同要求,设计、改装、应用到更多领域如:商品混凝土公司、码头吸砂等行业。

Product features:

1.The sand recycling, can effectively reduce the amount of sand losing to 5-10%. The problem of high modulus sand fineness , low dust content in artificial processing systems is solved. ·

2.Dewateringscreen , sieveplate and sprayer is synthetic plastic developed by several polymer factory through trial and error, making wear-life 5-6 times longer than steel plate and hard to block holes. ·

3.90% fine particulate material can be recovered through this system which has unparalleled technical and economic advantages than others.

4.The fully recovery of sand reduce the workload of sedimentation tank and lower the cost of cleaning up the sedimentation tank.

5.Sand recycling system minimize natural stacking time, transport directly and supply market.

6.According to user’s different requirements,machine may be designed and modified for supplying in more areas such as:commercial concrete company, wharf sands and other industries.

1014

1014